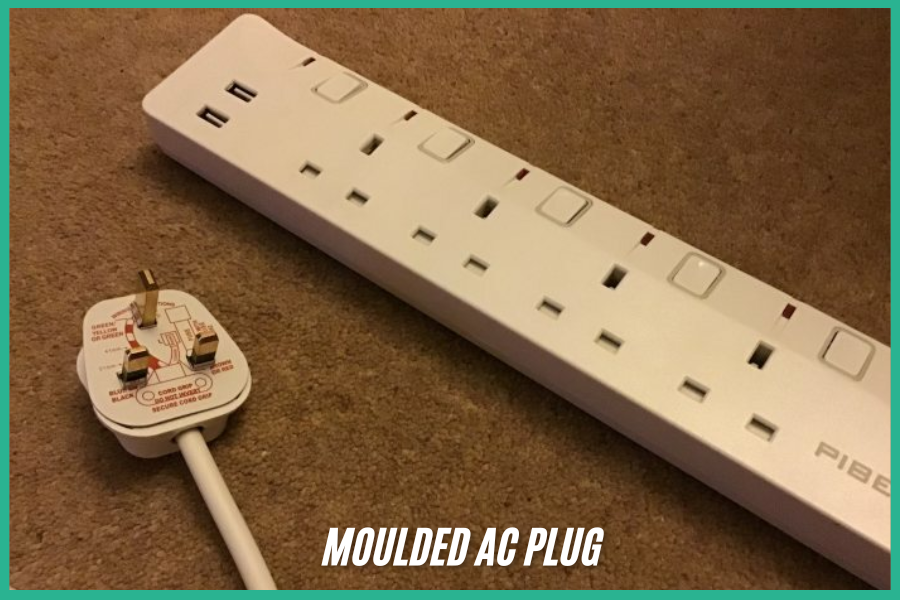

In today’s modern world, electricity is a crucial part of almost every aspect of our lives. Whether it’s for home appliances, office equipment, or industrial machines, electrical plugs and connections ensure the efficient transfer of power. Among the many types of plugs, the moulded AC plug stands out for its durability, safety, and practicality. This article provides an in-depth look at moulded AC plugs, including their design, applications, safety aspects, and more.

What is a Moulded AC Plug?

A moulded AC plug is a type of electrical connector that combines the plug and cable into a single, factory-sealed unit. Unlike traditional plugs, which require the user to manually connect the wires to the plug pins, moulded plugs are made with the wires permanently integrated into the plug casing during the manufacturing process. This design makes them more secure, durable, and safer to use compared to rewirable plugs.

The plug casing is typically made from a tough plastic or rubber material that is moulded around the cable, offering better protection against wear and tear. The connection is designed to be robust enough to withstand a range of environmental conditions while ensuring a reliable electrical connection.

Wiki

| Plug Type | Region | Pin Configuration | Voltage Rating | Current Rating | Applications | Standard |

| NEMA 5-15P | United States, Canada | 2 flat blades + 1 round grounding pin | 120V | 15A | Household appliances, office equipment, general use | NEMA 5-15 |

| IEC 60320 C13/C14 | Global (commonly used in IT) | 3 round pins (C14: male, C13: female) | 250V | 10A | Computer equipment, power supplies, servers | IEC 60320 |

| BS 1363 | United Kingdom, Ireland | 3 rectangular pins | 230V | 13A | Household appliances, kitchen devices, entertainment | BS 1363 |

| AS/NZS 3112 | Australia, New Zealand | 2 flat pins + 1 grounding pin | 230V | 10A | Household, commercial, industrial applications | AS/NZS 3112 |

| Schuko (CEE 7/4) | Europe (mainly Germany, France) | 2 round pins + 2 earth clips | 230V | 16A | Home appliances, power tools, office equipment | CEE 7/4 |

| South African Type M | South Africa, India | 3 round pins (large size) | 230V | 15A | High-power appliances, heavy-duty equipment | SANS 164-1 |

Components of a Moulded AC Plug

Moulded AC plugs usually consist of the following components:

- Plug Casing: The outer casing is typically made from a non-conductive material like thermoplastic or rubber. This casing is moulded to provide a protective shell around the cable and the internal wiring. The casing helps prevent electrical shocks, reduces wear from physical stress, and ensures that the internal wiring stays intact.

- Pins/Prongs: These are the metal parts of the plug that connect to the socket. They are typically made of brass or other conductive metals. The number of pins may vary depending on the plug’s design (e.g., two or three prongs for grounding).

- Cable: The electrical cable is permanently attached to the plug casing. The cable is usually insulated to ensure safety and is rated to carry a specific electrical load (e.g., 10A or 15A).

- Cord Strain Relief: This feature is designed to prevent the cable from being pulled out of the plug casing, offering additional security and preventing damage to the cord where it enters the plug.

Types of Moulded AC Plugs

Moulded plugs are available in several variations, each designed to meet specific standards and applications. Some of the most common types include:

NEMA 5-15P

The NEMA 5-15P is the most common type of AC plug used in the United States and Canada. It has two flat parallel blades and a round grounding pin. The NEMA 5-15P plug is typically used for standard 120V electrical outlets and is rated for 15A. These plugs are commonly found in household appliances, office equipment, and other devices that require basic power connections.

IEC 60320 C13/C14

The IEC 60320 standard is commonly used for computer and IT equipment. The C13 and C14 connectors are designed to ensure compatibility across various devices. The C13 plug is the female side, while the C14 is the male side, and they are often seen on power supplies for desktop computers, servers, and other IT devices. These plugs are standardized globally, which means they can be used in different countries without needing additional adapters.

BS 1363

The BS 1363 plug is standard in the United Kingdom and many other countries in Europe and Africa. This plug has three rectangular prongs and includes a built-in fuse for safety purposes. The fuse in the plug protects the connected device by breaking the circuit in case of a short or overload. The BS 1363 plug is rated for 13A and is used for various household appliances, including kitchen equipment, televisions, and more.

Australian/New Zealand Moulded Plug

In Australia and New Zealand, the AS/NZS 3112 standard applies. These plugs have two flat pins arranged in a V-shape, and they often have a third pin for grounding. The plugs are designed to be used with 230V outlets and are rated for 10A. These plugs are widely used in residential and commercial settings in both countries.

Why Choose Moulded AC Plugs?

Enhanced Safety

One of the key benefits of moulded AC plugs is the increased safety they provide. Since the plug and cable are permanently attached, there is no risk of the wiring becoming exposed, which can lead to short circuits, electric shocks, or fire hazards. Moulded plugs also ensure a secure connection to the power source, preventing loose or faulty connections that can cause electrical malfunctions.

Durability

Moulded AC plugs are designed to be more durable than traditional rewirable plugs. The sealed casing protects the internal wiring from physical damage, moisture, and dust. These plugs are more resilient in harsh environments, such as industrial settings or outdoor conditions. Their robust design makes them ideal for heavy-duty applications where wear and tear are common.

Easy to Use

Moulded plugs are convenient because they require no assembly. Once manufactured, they are ready for use straight out of the box, saving users time and effort. This feature is particularly beneficial for appliances and devices that need to be plugged in frequently, as it eliminates the need for ongoing maintenance or rewiring.

Moisture and Contaminant Resistance

The moulded design offers excellent protection against moisture, dust, and other contaminants that can damage electrical components. This is particularly important for appliances and tools used in outdoor or industrial environments. Moulded plugs help to ensure that the electrical components remain protected and operational even in less-than-ideal conditions.

Applications of Moulded AC Plugs

Moulded AC plugs are used in a wide variety of applications. Below are some common areas where they are found:

Consumer Electronics

Many household electronic devices come with moulded plugs. This includes everything from kitchen appliances like toasters and blenders to entertainment systems, computers, and televisions. The plug’s secure, durable design ensures these devices receive consistent and safe electrical power.

Industrial and Commercial Equipment

In industrial settings, heavy machinery and equipment require plugs that can handle substantial electrical loads while providing a secure connection. Moulded plugs are used in various machines, tools, and power supplies, offering reliability in high-demand environments.

Medical Equipment

The healthcare sector also benefits from moulded AC plugs. Many medical devices, including diagnostic machines, life-support equipment, and imaging tools, rely on these plugs to ensure continuous, safe operation. The robust nature of moulded plugs prevents electrical issues that could potentially disrupt life-saving treatments.

Power Tools

Power tools used in construction and DIY projects are often equipped with moulded plugs. These tools require durable and safe electrical connections to operate effectively in tough working conditions. Moulded plugs offer the necessary protection and longevity to handle the physical demands of power tools.

Moulded AC Plug Safety Considerations

While moulded AC plugs are generally safer than rewirable plugs, it’s important to follow certain guidelines to maintain their performance and safety.

Regular Inspections

Though the design is sealed, it’s still essential to regularly inspect moulded plugs for any visible damage. Over time, wear and tear from constant plugging and unplugging can cause the outer casing to crack, or the cord may become damaged at the point of entry into the plug. Any signs of damage should be addressed immediately by replacing the plug to avoid electrical hazards.

Avoid Overloading

Never overload a plug by connecting multiple devices that exceed the maximum current rating of the plug. This can cause the plug to overheat, potentially leading to electrical fires. Always check the power rating of the device and ensure that it falls within the specified limits for the plug.

Proper Insertion and Removal

Ensure the plug is inserted fully into the socket to make sure the connection is secure. When unplugging, avoid pulling on the cable itself, as this can damage the internal wiring. Instead, grip the plug firmly to avoid stress on the cable and the connection.

Environmental Considerations

Like many electrical components, the environmental impact of moulded AC plugs is a concern. These plugs are typically made from plastics and metals, which are not biodegradable and contribute to electronic waste. However, as the demand for more sustainable products grows, manufacturers are starting to focus on reducing the environmental impact of their production processes.

Recycling Challenges

Due to the integrated design of moulded plugs, they are more challenging to recycle than rewirable plugs. The fused plastic and metal components can be difficult to separate, which limits recycling options. Nonetheless, some companies are working towards more eco-friendly solutions, such as designing plugs that can be disassembled more easily.

Sustainable Manufacturing

The future of moulded AC plugs may involve the use of recycled materials or the development of biodegradable options. As the world moves toward more sustainable manufacturing practices, the goal will be to reduce waste while maintaining the plug’s safety and durability.

Conclusion

In summary, moulded AC plugs are an essential component in ensuring the safety, durability, and efficiency of electrical connections. Their permanent and sealed design offers several advantages over traditional rewirable plugs, including reduced risk of electrical hazards, enhanced protection against moisture and physical damage, and greater convenience in terms of installation and use. Whether for household appliances, industrial equipment, or medical devices, moulded plugs provide a reliable power connection that meets modern electrical standards.

The wide variety of moulded AC plugs available, each tailored for specific electrical systems and regions, ensures that they can be used in numerous applications across different sectors. Despite concerns about their environmental impact, manufacturers are continually working toward more sustainable practices. By understanding the benefits and safety considerations of moulded AC plugs, users can ensure the longevity and safe operation of their electrical systems, contributing to a reliable and secure power supply.

FAQs

1. What is the main advantage of using a moulded AC plug?

The primary advantage of a moulded AC plug is its enhanced safety and durability. The sealed design eliminates the need for manual wiring, reducing the risk of electrical faults and accidental exposure to live wires. It also provides protection against moisture, dust, and physical damage, making it ideal for various environments, including residential, industrial, and commercial settings.

2. Are moulded AC plugs safer than rewirable plugs?

Yes, moulded AC plugs are generally considered safer than rewirable plugs. Since the cable is permanently sealed inside the plug, there is no risk of wires becoming exposed or loose. This makes moulded plugs more reliable and less prone to electrical faults that could lead to shocks or fires.

3. Can I use a moulded AC plug for heavy-duty appliances?

Yes, moulded AC plugs are commonly used for heavy-duty appliances and industrial equipment. They are designed to handle high electrical loads and ensure secure and reliable connections. However, it’s important to select the appropriate plug based on the device’s power requirements and voltage specifications.

4. How do I maintain a moulded AC plug?

To maintain a moulded AC plug, regularly inspect it for visible damage, such as cracks or wear on the casing. Avoid overloading the plug by connecting too many devices at once, and always plug it in and unplug it properly without pulling on the cable. If you notice any signs of damage, replace the plug immediately to ensure safety.

5. Are there different types of moulded AC plugs for different countries?

Yes, moulded AC plugs come in various designs tailored for specific countries and their electrical systems. For example, the NEMA 5-15P is common in the United States, while the BS 1363 is used in the UK. These plugs differ in the number of pins and their shape to match the country’s power outlets and voltage ratings.

6. Can moulded AC plugs be recycled?

Moulded AC plugs are typically more difficult to recycle than traditional rewirable plugs due to their integrated design, which combines plastic and metal components. However, as manufacturers aim for more sustainable practices, efforts are being made to design plugs that are easier to recycle and use environmentally friendly materials.

7. How do I know the right moulded AC plug for my appliance?

To determine the right moulded AC plug, check the voltage and current rating of your appliance. Ensure the plug matches the required power load and is compatible with the electrical system in your country. You can usually find this information in the product manual or on the appliance’s label.

Explore Toronto’s pulse with breaking news and top stories at Enablers